PARAIMÉADAIRÍ TÁIRGE

| Ainm an Táirge | Píopa Tee |

| Méid | 1/2"-24" gan uaim, 26"-110" táthaithe |

| Caighdeánach | ANSI B16.9, EN10253-2, DIN2615, GOST17376, JIS B2313, MSS SP 75, saincheaptha, etc. |

| Tiús an bhalla | SCH5S, SCH10, SCH10S, STD, XS, SCH40S, SCH80S, SCH20, SCH30, SCH40, SCH60, SCH80, SCH160, XXS, saincheaptha agus araile. |

| Cineál | cothrom/díreach, neamhionann/laghdaitheach/laghdaithe |

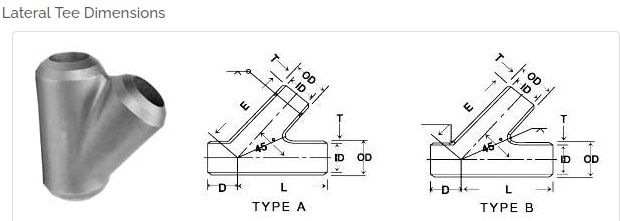

| Cineál speisialta | Tee scoilte, tee barraithe, tee cliathánach agus saincheaptha |

| Deireadh | Deireadh beibhéil/BE/táthú cnaipí |

| Dromchla | picilte, rolladh gaineamh, snasta, snasta scátháin agus araile. |

| Ábhar | Cruach dhosmálta:A403 WP304/304L, A403 WP316/316L, A403 WP321, A403 WP310S, A403 WP347H, A403 WP316Ti, A403 WP317, 904L, 1.4301,1.4307,1.4401,1.4571,1.4541, 254Mo agus araile. |

| Cruach dhosmálta déphléacsach:UNS31803, SAF2205, UNS32205, UNS31500, UNS32750, UNS32760, 1.4462,1.4410,1.4501 agus araile. | |

| Cóimhiotal nicil:inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H, C22, C-276, Monel400, Cóimhiotal20 etc. | |

| Feidhmchlár | Tionscal peitriceimiceach; tionscal eitlíochta agus aeraspáis; tionscal cógaisíochta, sceite gáis; gléasra cumhachta; tógáil long; cóireáil uisce, etc. |

| Buntáistí | stoc réidh, am seachadta níos tapúla; ar fáil i ngach méid, saincheaptha; ardchaighdeáin |

RÉAMHRÁ TEE

Is cineál feistis píopa é T-Phíopa atá T-chruthach agus a bhfuil dhá asraon aige, ag 90° leis an nasc leis an bpríomhlíne. Is píosa gearr píopa é le hasraon cliathánach. Úsáidtear T-Phíopa chun píblínte a nascadh le píopa ag uillinn cheart leis an líne. Úsáidtear T-Phíobáin go forleathan mar fheistis píopaí. Tá siad déanta as ábhair éagsúla agus tá siad ar fáil i méideanna agus bailchríocha éagsúla. Úsáidtear T-Phíobáin go forleathan i líonraí píblínte chun meascáin sreabhán dhá chéim a iompar.

CINEÁL TÉ

- Tá píopaí díreacha ann a bhfuil oscailtí den mhéid céanna acu.

- Bíonn oscailt amháin de mhéid difriúil agus dhá oscailt den mhéid chéanna ag tees píopa laghdaitheacha.

-

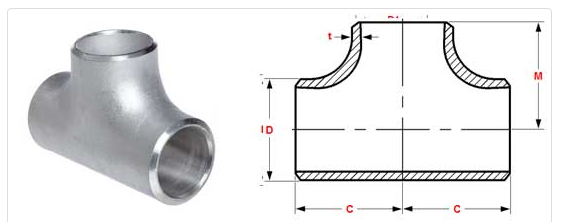

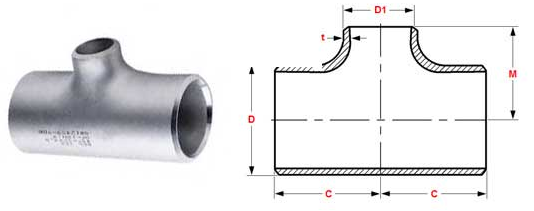

LÁNTAIS THOISEACHA ASME B16.9 TÉIDÍ DÍREACHA

Méid Ainmniúil na Píopa 1/2 go 2.1/2 3 go 3.1/2 4 5 go 8 10 go 18 20 go 24 26 go 30 32 go 48 Lasmuigh de Dia

ag Bevel (D)+1.6

-0.81.6 1.6 +2.4

-1.6+4

-3.2+6.4

-4.8+6.4

-4.8+6.4

-4.8Taobh istigh de Dia ag an Deireadh 0.8 1.6 1.6 1.6 3.2 4.8 +6.4

-4.8+6.4

-4.8Lár go Deireadh (C / M) 2 2 2 2 2 2 3 5 Balla Thk (t) Ní lú ná 87.5% de Thiús Balla Ainmniúil

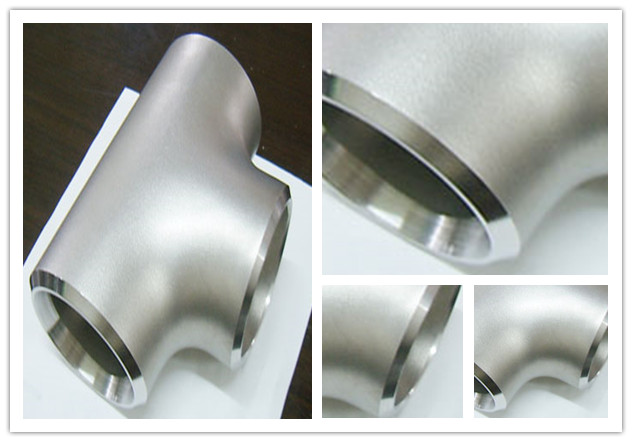

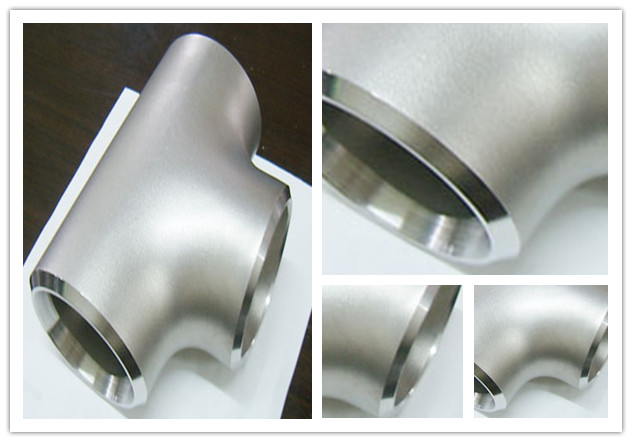

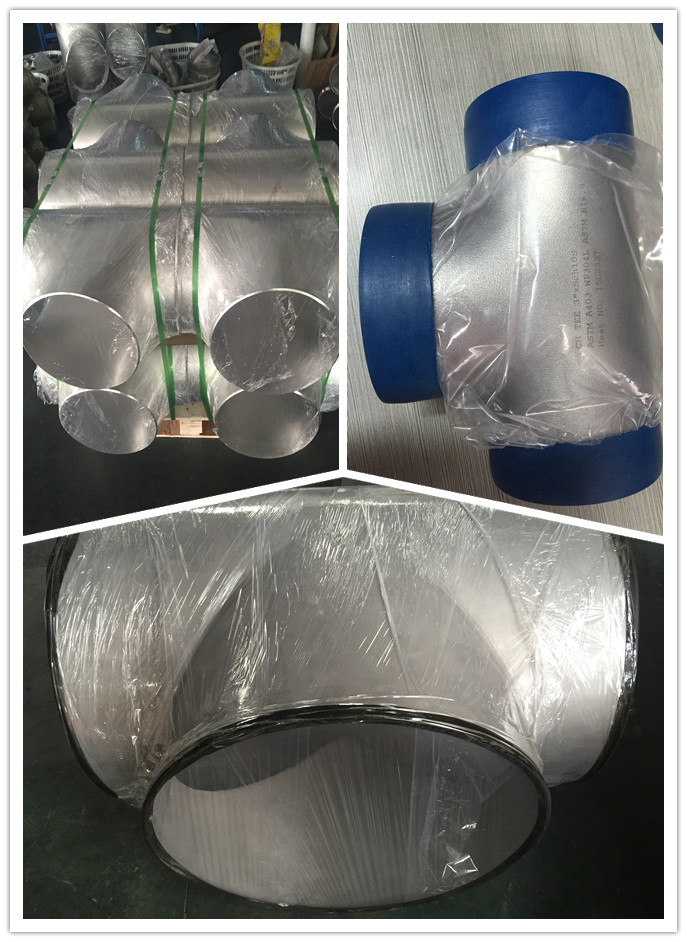

Grianghraif Mhionsonraithe

1. Foirceann beibhéil de réir ANSI B16.25.

2. Snas garbh ar dtús sula ndéantar rolladh gainimh, ansin beidh an dromchla i bhfad níos réidh

3. Gan lannú agus scoilteanna

4. Gan aon deisiúcháin táthú

5. Is féidir cóireáil dromchla a dhéanamh ar phicilte, ar rolladh gainimh, ar chríochnú neamhlonrach, ar snas scátháin. Cinnte, tá an praghas difriúil. Mar thagairt duit, is é dromchla rolladh gainimh an ceann is mó tóir. Tá praghas an rolla gainimh oiriúnach do fhormhór na gcliant.

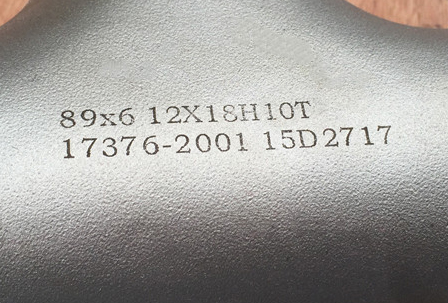

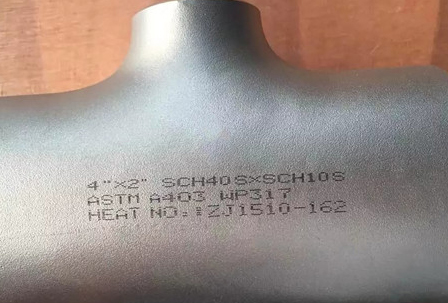

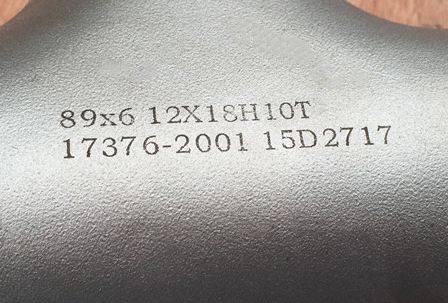

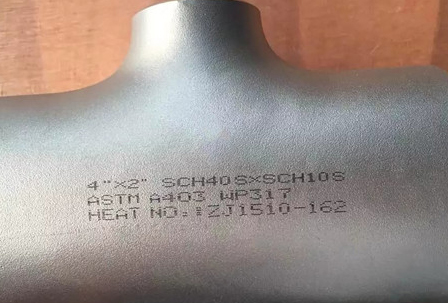

MARCÁIL

Is féidir obair mharcála éagsúil a dhéanamh ar d’iarratas. Glacaimid le do lógó a mharcáil.

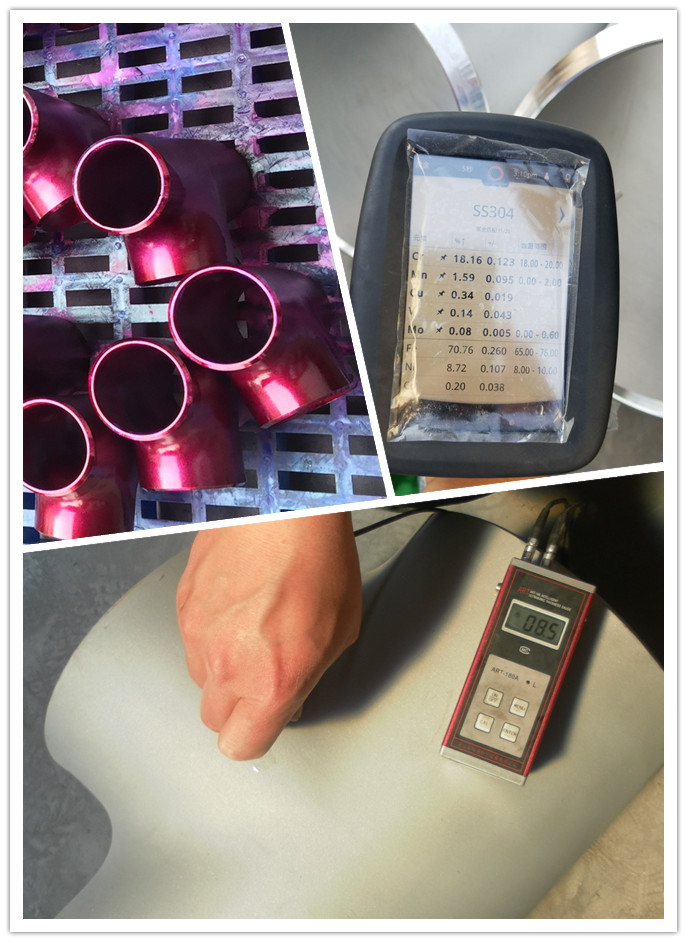

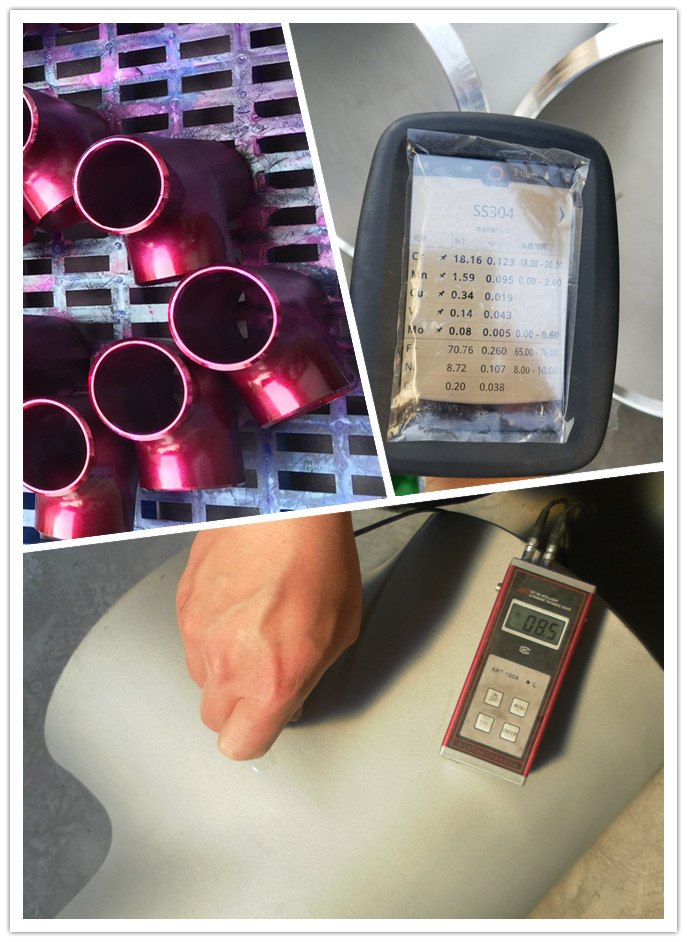

CIGIREACHT

1. Toisí toisí, laistigh den chaoinfhulaingt chaighdeánach.

2. Caoinfhulaingt tiús: +/- 12.5%, nó ar d'iarratas

3. PMI

4. Tástáil PT, UT, X-gha

5. Glac le cigireacht tríú páirtí

6. Soláthar MTC, deimhniú EN10204 3.1/3.2, NACE

7. Cleachtas E ASTM A262

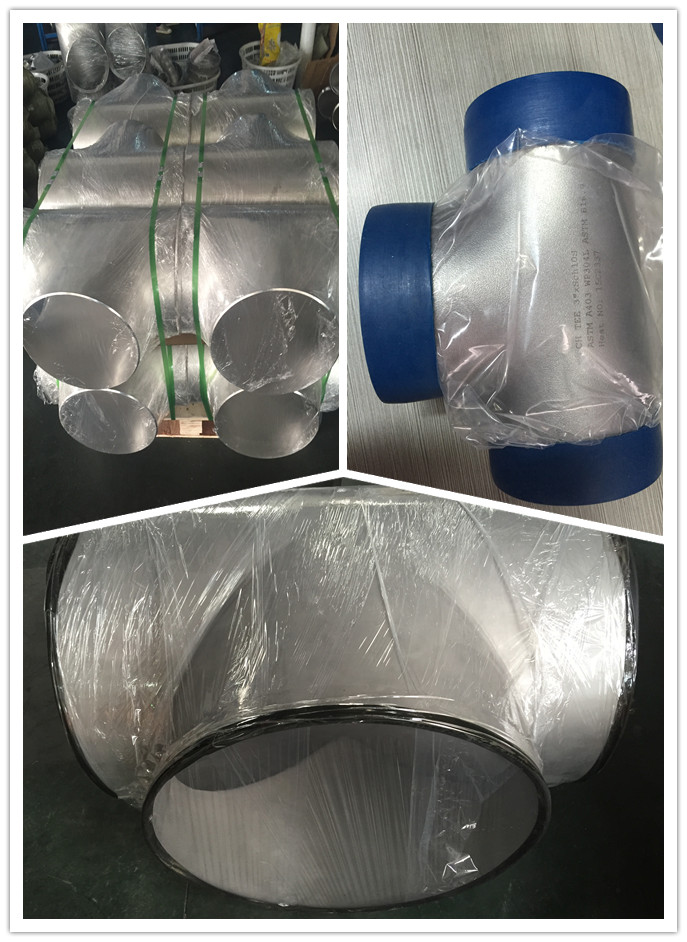

PACÁISTÍOCHT & LOINGSEOIREACHT

1. Pacáilte le cás sraithadhmaid nó pailléad sraithadhmaid de réir ISPM15

2. cuirfimid liosta pacála ar gach pacáiste

3. Cuirfimid marcanna loingseoireachta ar gach pacáiste. Is féidir na focail mharcála a roghnú ar d'iarratas.

4. Tá gach ábhar pacáiste adhmaid saor ó dheochanna

Grianghraif mhionsonraithe

1. Foirceann beibhéil de réir ANSI B16.25.

2. Snas garbh ar dtús sula ndéantar rolladh gainimh, ansin beidh an dromchla i bhfad níos réidh

3. Gan lannú agus scoilteanna

4. Gan aon deisiúcháin táthú

5. Is féidir cóireáil dromchla a dhéanamh ar phicilte, ar rolladh gainimh, ar chríochnú neamhlonrach, ar snas scátháin. Cinnte, tá an praghas difriúil. Mar thagairt duit, is é dromchla rolladh gainimh an ceann is mó tóir. Tá praghas an rolla gainimh oiriúnach do fhormhór na gcliant.

Is cineál feistis píopa é T-Phíopa atá T-chruthach agus a bhfuil dhá asraon aige, ag 90° leis an nasc leis an bpríomhlíne. Is píosa gearr píopa é le hasraon cliathánach. Úsáidtear T-Phíopa chun píblínte a nascadh le píopa ag uillinn cheart leis an líne. Úsáidtear T-Phíobáin go forleathan mar fheistis píopaí. Tá siad déanta as ábhair éagsúla agus tá siad ar fáil i méideanna agus bailchríocha éagsúla. Úsáidtear T-Phíobáin go forleathan i líonraí píblínte chun meascáin sreabhán dhá chéim a iompar.

Is cineál feistis píopa é T-Phíopa atá T-chruthach agus a bhfuil dhá asraon aige, ag 90° leis an nasc leis an bpríomhlíne. Is píosa gearr píopa é le hasraon cliathánach. Úsáidtear T-Phíopa chun píblínte a nascadh le píopa ag uillinn cheart leis an líne. Úsáidtear T-Phíobáin go forleathan mar fheistis píopaí. Tá siad déanta as ábhair éagsúla agus tá siad ar fáil i méideanna agus bailchríocha éagsúla. Úsáidtear T-Phíobáin go forleathan i líonraí píblínte chun meascáin sreabhán dhá chéim a iompar.

LÁNTAIS THOISEACHA ASME B16.9 TÉIDÍ DÍREACHA

| Méid Ainmniúil na Píopa | 1/2 go 2.1/2 | 3 go 3.1/2 | 4 | 5 go 8 | 10 go 18 | 20 go 24 | 26 go 30 | 32 go 48 |

| Lasmuigh de Dia ag Bevel (D) | +1.6 -0.8 | 1.6 | 1.6 | +2.4 -1.6 | +4 -3.2 | +6.4 -4.8 | +6.4 -4.8 | +6.4 -4.8 |

| Taobh istigh de Dia ag an Deireadh | 0.8 | 1.6 | 1.6 | 1.6 | 3.2 | 4.8 | +6.4 -4.8 | +6.4 -4.8 |

| Lár go Deireadh (C / M) | 2 | 2 | 2 | 2 | 2 | 2 | 3 | 5 |

| Balla Thk (t) | Ní lú ná 87.5% de Thiús Balla Ainmniúil | |||||||

Tá lamháltais thoisí i milliméadair mura luaitear a mhalairt agus tá siad cothrom ± ach amháin mar a luaitear.

Marcáil

Is féidir obair mharcála éagsúil a dhéanamh ar d’iarratas. Glacaimid le do lógó a mharcáil.

Cigireacht

1. Toisí toisí, laistigh den chaoinfhulaingt chaighdeánach.

2. Caoinfhulaingt tiús: +/- 12.5%, nó ar d'iarratas

3. PMI

4. Tástáil PT, UT, X-gha

5. Glac le cigireacht tríú páirtí

6. Soláthar MTC, deimhniú EN10204 3.1/3.2, NACE

7. Cleachtas E ASTM A262

Pacáistiú & Loingseoireacht

1. Pacáilte le cás sraithadhmaid nó pailléad sraithadhmaid de réir ISPM15

2. cuirfimid liosta pacála ar gach pacáiste

3. Cuirfimid marcanna loingseoireachta ar gach pacáiste. Is féidir na focail mharcála a roghnú ar d'iarratas.

4. Tá gach ábhar pacáiste adhmaid saor ó dheochanna

Is comhpháirteanna ríthábhachtacha sa chóras píopaí iad feistis phíopaí, a úsáidtear chun sreabháin a nascadh, a atreorú, a atreorú, a athrú méide, a shéalú nó a rialú. Úsáidtear go forleathan iad i réimsí ar nós tógála, tionscail, fuinnimh agus seirbhísí bardasacha.

Príomhfheidhmeanna:Is féidir leis feidhmeanna a dhéanamh amhail píopaí a nascadh, treo sreafa a athrú, sreafaí a roinnt agus a chumasc, trastomhais píopaí a choigeartú, píopaí a shéalú, rialú agus rialáil.

Raon Feidhme:

- Soláthar uisce agus draenáil foirgnimh:Úsáidtear uillinneacha PVC agus tris PPR le haghaidh líonraí píopaí uisce.

- Píblínte tionsclaíocha:Úsáidtear flainsí cruach dhosmálta agus uillinneacha cruach cóimhiotail chun meáin cheimiceacha a iompar.

- Iompar fuinnimh:Úsáidtear feistis píopa cruach ardbhrú i bpíblínte ola agus gáis.

- HVAC (Téamh, Aeráil agus Aerchóiriú):Úsáidtear feistis píopa copair chun píblínte cuisneáin a nascadh, agus úsáidtear hailt sholúbtha chun creathadh a laghdú.

- Uisciúcháin talmhaíochta:Éascaíonn nascóirí tapa cóimeáil agus díchóimeáil córas uisciúcháin sprinkler.

-

Laghdaitheoir Píopa Cruach Bán SCH 40 Cruach Dhosmálta...

-

Cruach chóimhiotail DN500 20 orlach A234 WP22 gan uaim 90 ...

-

Feistiú píopa cruach gan uaim dubh A234WPB neamhchothrom ...

-

Feistiú Píopa A234WPB ANSI B16.9 Uillinn Cóimhiotal Steel ...

-

Feistiú Píopa Butt-Weld Cruach Dhosmálta 304L ...

-

Feistiú píopa uillinn DN50 50A sch10 90 LR gan uaim ...